------------------------------------------------------ Enclosed Specification -----------------------------------------------------

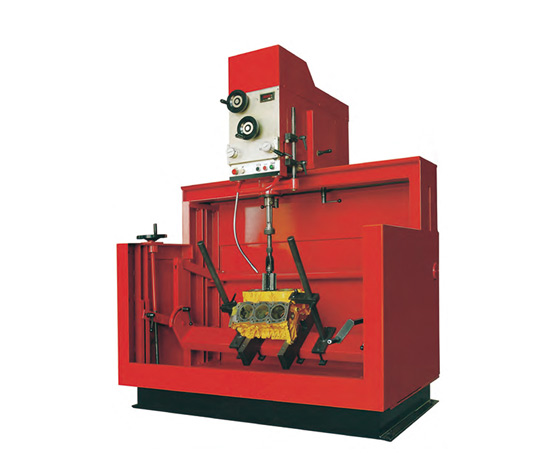

1. Turret Milling Machine

Model: X6333

Features:

Turret milling machine are widely used for processing flat face, slope face, key-way, key groove, slot and drilling, reaming, boring in almost every country all over the world because of the high quality with competitive price.

Taiwan original milling head and 3 axes Taiwan lead-screws make sure our milling machines performance better than others.

Compare with small milling machine, we choose the 5HP milling head with diameter 100mm quill for X6325C and X6325D. 5HP milling head get the better performance than 3HP milling head, which can make the machine more efficiently and profitable. Then we make it happened by changing the design and making the ram structure much more stranger to afford the weight increment.

NSK P4 bearings are adopted in spindle to improve accuracy of machine and increase the working life.

Specifications:

Model | X6333 | X6333A | ||

Table Size | 330×1370mm (13"×54") | |||

Table Loading | 380kg | |||

Longitudinal Travel | Manual | 820 | ||

Auto (Power Feed) | 820 | |||

Cross Travel | Manual | 380 | ||

Auto (Power Feed) | 380 | |||

Knee Vertical Travel | Manual | 460 | ||

Auto (Power Feed) | 460 | |||

Longitudinal Travel Feed Speed | 1000mm/min | |||

Cross Travel Feed Speed | 1000mm/min | |||

Knee Vertical Travel Feed Speed | 350mm/min | |||

T Slots (Qty×Size) | 3×16 | |||

Ram Travel | 500mm | |||

Distance between Spindle Nose and Table Surface | 0-450mm | |||

Spindle Hole Taper | ISO40 | |||

Spindle Travel | 127mm | |||

Spindle Speed | Standard: 16 Steps, 66-4540rpm (50Hz), Optional: 60-3600 (Variable) | |||

Quill Feed Rate | 3 Steps: 0.04/0.08/0.15mm/rev | |||

Spindle Motor | 3.7kw/5HP | |||

Head Swivel | ±90° | |||

Head Tilting | ±45° | |||

Dimension of Machine | 2600×2500×2300mm | |||

Dimension of Package | 1800×2020×2200mm | |||

G.W. | 2000/2200kg | 2050/2250kg | ||

Standard Accessories:

Draw Bar | Manual Oil Pump |

Working Lamp | Tools Box and Tools |

Operating Manual | Z-axis Lifting Motor |

Model | TM6325/TM6325A/TM6325B | |

Table size(mm) | 254x1270(10’’x50’’) | |

Long travel(mm) | 850/950 | |

Cross travel(mm) | 420/400 | |

Vertical travel(mm) | 420 | |

T-slot No. and size | 3x16 | |

Ram travel(mm) | 470 | |

Distance from spindle nose to table surface(mm) | 0-405 | |

Spindle hole taper | Standard:R8 Optional: ISO30/ISO40 | |

Spindle travel(mm) | 127 | |

Spindle speed | Standard: 16steps | |

Optional : stepless Variable: 65-4500 | ||

Auto quill feed | Three steps: 0.04/0.08/0.15 mm/revolution | |

Spindle motor | 2.25kw/3HP | |

Head swivel | 90° | |

Head tilting | 45° | |

Dimension of package | One miller per case | 1516x1550x2080 |

Two miller per case | 1680x1790x2170 | |

Three miller per case | 1650x2285x2235 | |

G.W. | 1320 | |

TM6325:

|

TM6325A: 1,Double 55°swallowtail guidway is adopted on both Y and Z axis,So it is easy to adjust 2, The guideway on saddle is lined with TF wearable material |

TM6325B: 1,55°swallowtail guidway is adopted on Z axis and rectangular guidway on Y axis 2,Adopted strengthen rib on both sides of the columb,that makes the machine rigidly and beautiful |