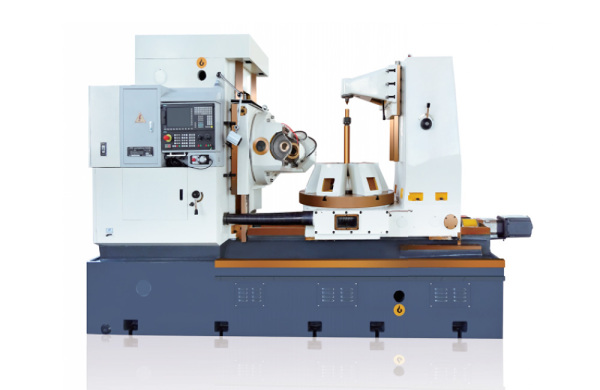

Characteristics

- The modular machine concept has been consistently applied to the large machines of this series, guaranteeing an outstanding cost-benefit ratio and low maintenance costs.

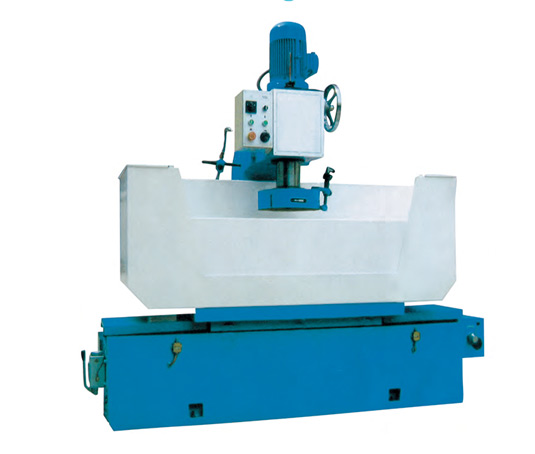

- Cast-iron machine bed of maximum static and dynamic rigidity with integrated fluid circulation for thermal stability.

- The worktable is driven high quality, high precision worm and worm wheel gear drive.

- Linear slides are provided with backlash-free pretension ball screws. AC servo-drives, cast-iron guideways, resin-coated for optimum vibration absorption. Controlled pulse lubrication is used..

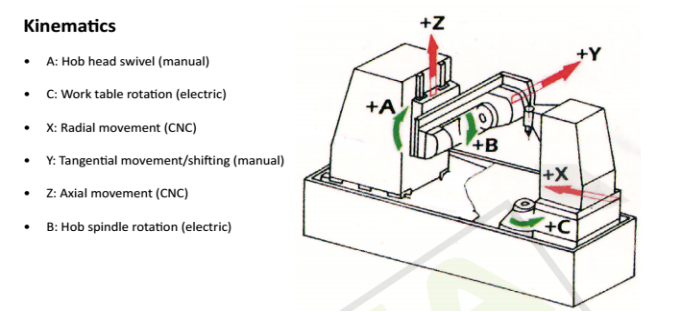

- With vertical design, the worktable moves to realize feed motion.

- CNC axes are driven through preloaded ball screws. It can cut gears with crowning and slightly tapered teeth by axial and radial co-ordinate control.

- High precision hydraulic components.

- Main guideways are coated with Teflon, the main body is annealed cast structure and solid construction which gives high rigidity.

- Manual hob shifting.

- Separate cooling systems.

- Precision ball screws are used for CNC axes to ensure high moving and positioning accuracy.