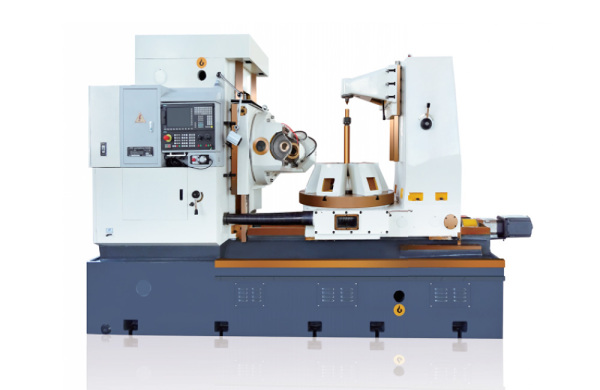

This model is 4 NC axes with taper device.

It not only can cut extrusion dies and blanking punches vertically and horizontally, but also has taper cut and different profile at top and bottom machining abilities.

The cut taper angle can be 0 to 60 degree arbitrarily.

NC Controller:

*Industry PC from AdvantechR Taiwan configuration:

2 ICA-6806/681-400

2 128M SD

2 Ethernet interface 10/100Mb

2 RS232

2 USB interface

2 Floppy driver

2 Keyboard

2 Mouse

2 15" LCD

Background editing and program running, thus make it possible to edit a program when the machine working.

Graphic display online machining trace and workpiece profile.

Automatic graphic edit and generate the program.

Translate AutoCADR files to program automatically.

ISO standard G code programming, compatible with 3B code.

HF program and control system features:

2 Graphic edit based on AutoCADR, it is easy to learn in a short time and use rapidly and correctly.

2 Advanced e-Function, can connect machine to Ethernet, thus optimized resource management and make non paper working possible.

2 English operation menus included all parts of WEDM machining technology, e.g. electrical presetting, mechanical presetting, choose parameters table, personalize erosion parameters.

2 Complete parameters tables for different kinds of materials.

2 Rules for jobs’ routine and peripherals make it possible bring demanded workpiece out quickly and high quality.

NC system capabilities:

2 Programming and machining are at same time.

2 All operations can be done by mouse clicks.

2 Online machining trace display.

2 4 axes interpolation in 3 dimensions and compensate backslash automatically.

2 Auto save all data when cut off the power supplier and restore them after restart.

2 Find home point, edge positioning and find workpiece center automatically.

2 Step movement for each axis.

2 Rotate, zoom and mirror drawings.

2 Program reverse cut and alarm messages display.

2 Start working at any code line.

2 Machining same workpieces according to a programmed matrix or round.

2 Backslash compensations.

2 Eliminates wire lag in high speed cutting (especial for sharp angle cuttings).

2 All program and control functions are displayed on screen.

2 Automatic graphic edit and generate the program and translate AutoCADR files to program automatically.

2 ISO standard G code programming, compatible with 3B code.

2 Auto shunt down the machine after finished program.

2 Multi-cutting function.

2 Reverse runs automatically when short circuit occurs.

2 Wire break protection function.

2 Linear and circular interpolation.

*Adopts import high precision ball scales and guides. They help the machine response movement commands rapidly, smoothly and accurately and keep the whole machine in a stable state.

*Adopts self service lubrication system in pulleys’ bearings. It can extend the bearings life 3 times more.

*Adopts anti-wave device in the wire running system. It will improve machining precision and extern the life of wire.

Moveable clamps on two slides on the worktable. It will save time when installing workpiece.

*Integrated lubrication system in all moveable parts to keep them can be lubricated well.

*Wire runs by constant force structure, improves best finishing result in Ra.

New designed machine body structure, a low and wide basement, improves machine body’s stiffness and stability. The body is built by high quality casting iron and high casting technology.

*Adopts AC servo motors or step motors to move the worktable. The motor is connected to ball screw directly to avoid gears box compensation and keeps machine stable.

Adopts advanced frequency conversion technology to adjust wire roller’s speed. It can control wire’s speed smoothly and arbitrarily in different conditions.

*Good performance and high power pulse generator can realize high efficiency machining even for big thickness workpiece. It can cut various materials like different model alloy steels, aluminum alloys, copper, titanium, carbide, ultra hard materials, conducting china, ultra heat materials and etc.

*The generator adopts anti stripe erosion technology as well, improves best surface finishing roughness in Ra.

*Two patent technology in taper structure: 1) Big taper structure consisted by 4 link bars. 2) Precision small taper structure by planetary movement. These two structures share one great idea that keeps wire and pulley in vertical regardless any taper angle to ensure machining precision and surface roughness. We can get the domestic best precision in taper cutting. And it can realize 4 axes linkage movement to machining equal cone profiles, arbitrary cone profiles and top and bottom different profiles.

Power generator, NC system and electrical equipments are divided into 3 modules. They are combined optimized to resist electro magnetic influences.

Every machine is tested and inspected carefully and strictly before selling. We do 100 hours continue test with full load and another 100 hours not continues test with peak load.

Training courses for WEDM operators and workers are held periodically at our training center. Using simulators and machinery as well as detailed documentation, our specialists train our customer in:

2 Correct use of our machines.

2 WEDM technology.

2 Programming in order to assure a complete and optimal use of our systems.

Item | Specification | Comment | |

1 | Worktable travel (X×Y) | 250×320mm | |

2 | Worktable size (L×W) | 336×520mm | *Bigger table and easier clamping. |

3 | Taper angle/height | 0-60°/100mm (OPTION) | 6°/80mm as standard |

4 | U / V travel | 200mm (OPTION) | *Make it possible to machining big taper angle profile in high precision. |

5 | Max. workpiece thickness | 300mm | |

6 | Max. load capability | 250Kg | |

7 | Best roughness | Rɑ ≤ 1.0um | |

8 | Max. machining speed | ≥80 – 150mm2/min | Alloy steel ≥100; Copper ≥80; Aluminia≥200; Titanium ≥70. |

9 | Machining precision | ≤0.01mm | |

10 | Movement equivalent | 0.001mm | |

11 | Wire diameter | Φ0.10 –Φ0.25mm | |

12 | Wire traveling speed | 7 – 11m/s | |

13 | Machine weight | 950Kg | |

14 | Machine extend dimension | 1300×900×1450mm | |

15 | Max. erosion current | 6A | Peak current is 45 – 65A. |

16 | Erosion voltage | 55 / 65 / 75 / 85 Vdc | 4 sets of DC voltage. |

17 | Pulse width | 5 – 80us | 5 sets of pulse width. |

18 | Pulse duty | 1:4-1:8 ( Pulse on : Pulse off ) | It possible adjusts continuously. |

19 | Input voltage | ( 3P 380Vac±10% 50Hz ) | |

20 | Rated power | 2KVA | |

21 | Electrical cabinet weight | 200Kg | |

21 | Electrical cabinet dimension | 700×600×1750mm | |

22 | Working solution | Deionized water | |

23 | Reservoir capacity | 100L | |

24 | Filter | Dielectric type |

Machine precision | ||

1 | Movement equivalent of X,Y axes | 0.001mm |

2 | Positioning precision of X axis | ≤0.02mm |

3 | Repetitive positioning precision of X axis | 0.002mm |

4 | Positioning precision of Y axis | ≤0.02mm |

5 | Repetitive positioning precision of Y axis | 0.002mm |

6 | Verticalness of wire against work table | ≤0.01mm |

7 | Radial vibration of wire roller | ≤0.03mm |