Quotation

Validity date: 45days | ||||

Model Description QTY | ||||

TF3015EDGE+ Fiber Laser Cutting Machine with exchange working table | Effective cutting area | 3000x1500mm | ||

Laser max cutting thickness | 12mm(Carbon Steel) | 1 set | ||

6mm(Stainless Steel) | ||||

With Feibo 1000W, Price: FOB Shanghai $48,000 | ||||

Production time | Within 45 days after advance payment | |||

Payment term | 30% T/T in advance, balance before delivery | |||

Packing | Plywood case and tray | |||

Container requirement | 40’GP container | |||

Warranty: 12months from the date of bill of lading issued.(Seller will supply free spare parts by mail)

Installation, training and commissioning service terms:

Time cost: 1 engineers 15-20 days

Engineer’s visa fee, round-trip flight tickets from Shanghai to user’s spot, food and accommodation cost undertaken by buyer.

Engineer’s subsidy 100.00 USD per day, per person.

Buyer takes responsibility to arrange a Chinese speaking translator to be assistance during installation and training.

*Product images and cutting parameter inside of this file are for illustrative purposes only and may differ from the actual product!

1. Machine Parameter

Cutting Size | 3000×1500 mm |

X Axis Cutting Size | 3000 mm |

Y Axis Cutting Size | 1500 mm |

Z Axis Lifting Distance | 120 mm |

Max Position Speed(Each Axis) | 80 m/min |

Max Position Speed(XY Joint-Speed) | 113 m/min |

X、Y Axis Position Accuracy | 0.05 mm |

X、Y Repeat Position Accuracy | 0.025 mm |

Laser Power | Feibo 1000W |

Cutting Thickness | MS 12mm; SS 6mm |

Noise | <75db |

Working Voltage | 3 Phase 380V±5%/50Hz |

Outer Dimension(L×W×H) | 10.5×3.6×2.1m |

Power Requirement | 28.3 kW |

2. Main Components

Detailed Specification | |||

No. | Name | Brand | Note |

1 | Fiber Laser Generator | Feibo 1000W | |

2 | Fiber Laser Head | Szworthing | |

3 | Machine Body | OUR FACTORY | Welding Body Aging Treatment |

4 | Beam | OUR FACTORY | Aluminium Cast Beam Aging Treatment |

5 | Cutting Table | OUR FACTORY | Transferable Tables |

6 | Precision Gear Box | Taiwan APEX / Japan SHIMPO | |

7 | X、Y Axis Rack And Pinion | Taiwan YYC / Sweden LINDEN | |

8 | Z Axis Ball Screw | Taiwan Hiwin / Taiwan STAF | |

9 | Linear Guide | Taiwan Hiwin / Taiwan STAF | |

10 | Gas System | Japan SMC | |

11 | Cooling Unit | S&A | |

12 | Electric Components | France Schneider | |

13 | CNC Controller | Cypcut | Including Control Software |

14 | AC Servo Motor And Driver | Japan Yaskawa | |

15 | CAD/CAM Nesting Software | CypCut | |

16 | Electric Cabinet And Operation Station | OUR FACTORY | |

17 | Dust Collection System | Standard Brand | Including Blower |

18 | Scrap Collection System | OUR FACTORY | |

3. TAYOR Laser Machine Cutting Function

Laser Cutting Function | ||

No. | Function | Description |

1 | Height Follow-Up | Torch Move Up And Down According To Plate Height |

2 | Power Control | Laser Power Control According To Slope |

3 | Reverse Function | Reverse To Execute NC Program |

4 | Breakpoint Return | Return To Breakpoint After Recovery |

5 | Multi Piercing | Pulse, Blasting, Progress, High-Speed |

6 | Lead Line | Set Lead Line Parameter |

7 | Auto Edge-Finding | Find Cutting Piece Coordinate Automatically |

8 | Leapforg Function | Leapforg To Improve Cutting Efficiency |

9 | Common Line | Common Line To Improve Cutting Efficiency |

10 | Marking Function | Mark Any Shape On Plate |

4.Cutting Thickness And Speed

Cutting parameter based on SS(Stainless Steel SS304); MS(Mild Steel Q235). Below cutting parameters are for reference only!

Material | Thickness | Recommend Cutting Speed | Max Cutting Speed | Power | Cutting Gas | Gas Pressure | Focus | Nozzle Model | Defocusing |

SS | 1 | 19000 | 24000 | 1000 | N2 | 8 | 0 | 1.5 | 0.7 |

SS | 2 | 5300 | 5500 | 1000 | N2 | 9 | -1 | 1.5 | 0.7 |

SS | 3 | 2700 | 3000 | 1000 | N2 | 9 | -2 | 2 | 0.7 |

SS | 4 | 1500 | 1800 | 1000 | N2 | 9 | -2 | 2 | 0.7 |

SS | 6 | 600 | 680 | 1000 | N2 | 10 | -3 | 2.5 | 0.7 |

MS | 1 | 9000 | 10000 | 1000 | O2 | 1 | 2 | 1.2 | 0.7 |

MS | 1.5 | 8000 | 9000 | 1000 | O2 | 1.4 | 2 | 1.2 | 0.7 |

MS | 2 | 6200 | 7000 | 1000 | O2 | 1.4 | 2 | 1.2 | 0.7 |

MS | 3 | 3500 | 4000 | 1000 | O2 | 1.2 | 2 | 1.2 | 0.7 |

MS | 5 | 1800 | 2000 | 1000 | O2 | 0.6 | 2 | 1.2 | 0.7 |

MS | 6 | 1600 | 1800 | 1000 | O2 | 0.8 | 2 | 1.5 | 0.7 |

MS | 8 | 1100 | 1200 | 1000 | O2 | 0.6 | 2 | 1.5 | 0.7 |

MS | 10 | 900 | 1000 | 1000 | O2 | 0.7 | 2.5 | 1.5 | 0.7 |

MS | 12 | 700 | 800 | 1000 | O2 | 0.7 | 2.5 | 1.5 | 0.7 |

5. Machine Rough Consumption 1000W | |||||||

A> Total Power Consumption | |||||||

Machine Part | Power | Power Consumption | Note | ||||

(kW) | (kW/Hour) | ||||||

Laser Generator | 5.8 | ≦28.3 | Due to the power price is different in every country, so I can only give power consumption, couldn’t give total price cost | ||||

CNC Table | 12 | ||||||

Cooling Unit | 5.5 | ||||||

Extractor | 5 | ||||||

B> Gas Consumption | |||||||

Gas | Consumption | Note | Note | ||||

(Minute/Bottle) | |||||||

O2 | 60 | Calculated based on 1mm MS Plate | Due to the gas price is different in every country, so I can only give gas consumption, couldn’t give total price cost | ||||

N2 | 15 | Calculated based on 1mm SS Plate | |||||

C> Consumables | ||||

Consumables | Life(Hour) | Unit Price | Total Cost | Note |

(USD/Piece) | (USD/Hour) | |||

Protective Mirror | ≧240 | 43 | 0.18 | If working environment is good, then consumables’ life will be longer |

Nozzle | ≧600 | 21.4 | 0.04 | |

Ceramic Ring | ≧1500 | 108 | 0.07 | |

Total | 0.29 USD/Hour | |||

Total Consumption | ||||

Item | Power Consumption | Gas Consumption | Consumables | Note |

(USD/Hour) | ||||

O2 | ≦28.3 kW/Hour | 60 (Minute/Bottle) | 0.29 USD/Hour | Calculated based on 1mm MS Plate |

N2 | ≦28.3 kW/Hour | 15 (Minute/Bottle) | 0.29 USD/Hour | Calculated based on 1mm SS Plate |

CNC Controller Cypcut(Build-In Type)

- CNC Controller Cypcut Build-In Type

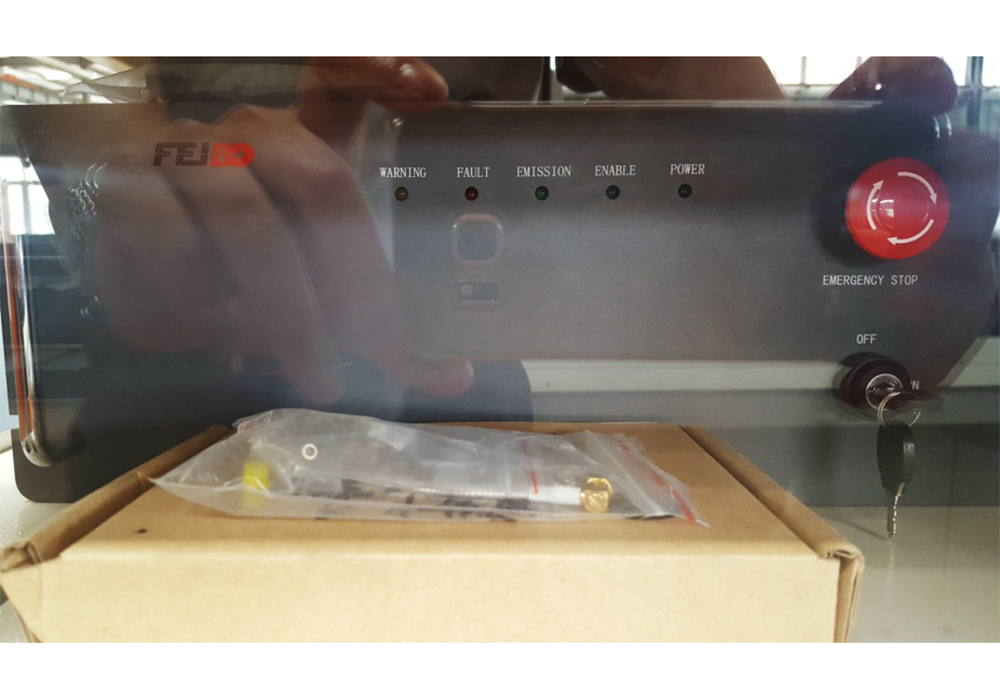

Fiber Laser Generator

- Fiber Laser Generator Feibo 1000W

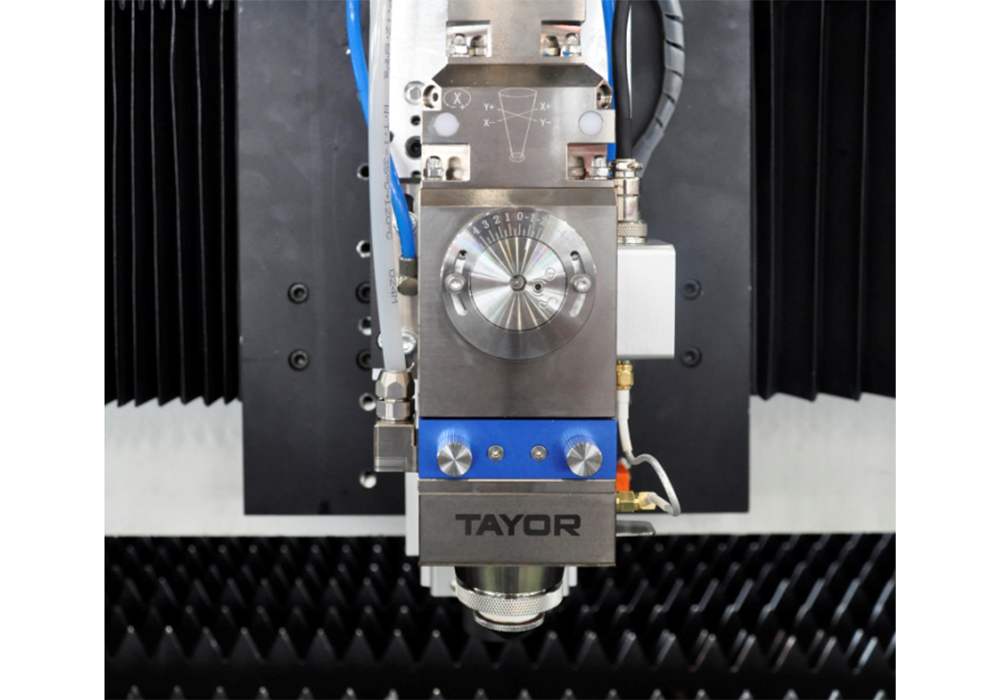

Fiber Laser Cutting Head

- Fiber Laser Cutting Head

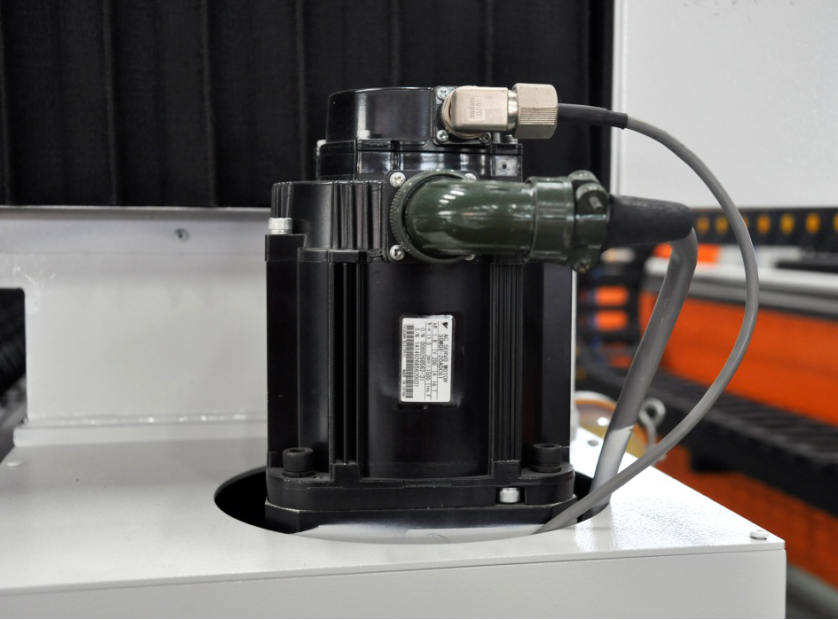

Yaskawa AC Servo Motor

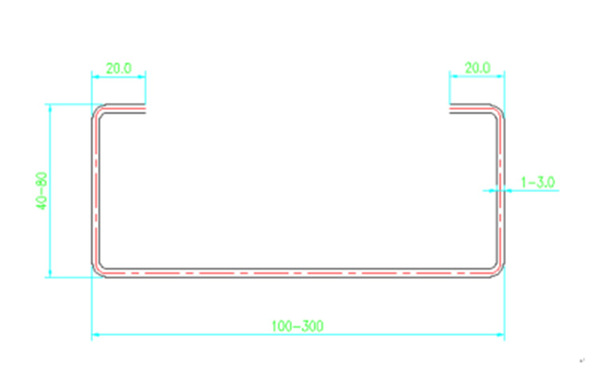

Helical Rack And Pinion

- Cutting Sample

Cutting Sample