NO. | Name | Value | Unit |

1 | Normal force | 630 | KN |

2 | Length of working table | 2500 | mm |

3 | Distance between columne | 2020 | mm |

4 | Throat depth | 250 | mm |

5 | Ram travel | 100 | mm |

6 | Approaching speed | 90 | Mm/s |

7 | Working speed | 8 | Mm/s |

8 | Adjustment of ram travel | 70 | Mm/s |

9 | Day light | 335 | mm |

10 | Motor power | 5.5 | kw |

NO. | Name | manufacturers |

1 | Hydraulic Valve | Rexroth |

2 | Main motor | Siemens |

3 | Main seals | NOK |

4 | Stroke switch , pushbutton | SCHNEIDER |

5 | Relay , contactor | SCHNEIDER |

6 | Inner gear pump | Sunny |

7 | Control system | E-21 or DA41 system |

8 | Servo motor | ESTUN |

The frame is assembled in monoblock after welding, it is processed by heating treatment, machining by CNC Floor Boring and Milling center, ensuring the rigidity and processing accuracy of the frame. |

|

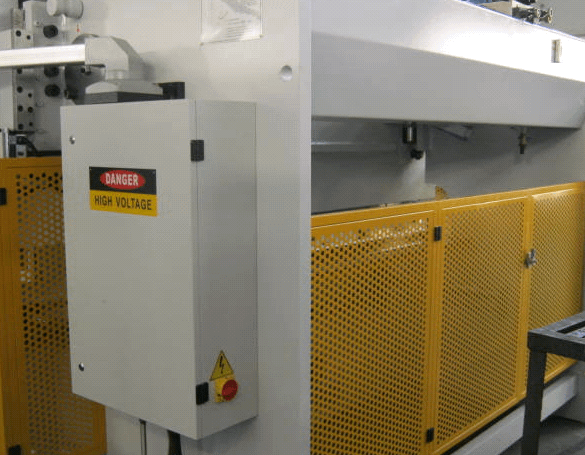

CE protection cover |

|

Famous Pipe Connector (EMB , Avoid Oil leakage) Complete Hydraulic station ( Include small pilot operated check valve, overflow valve, safty valve, Rapid valve) |

|

Dul Hand control Foot padel With Emegency stop and Aircraft connector and wire cover ( Also as CE certificate) |

|

Shipment, packing with steel pallet. Keep it safe when shiping, and easy to Unloading from the container. |

|

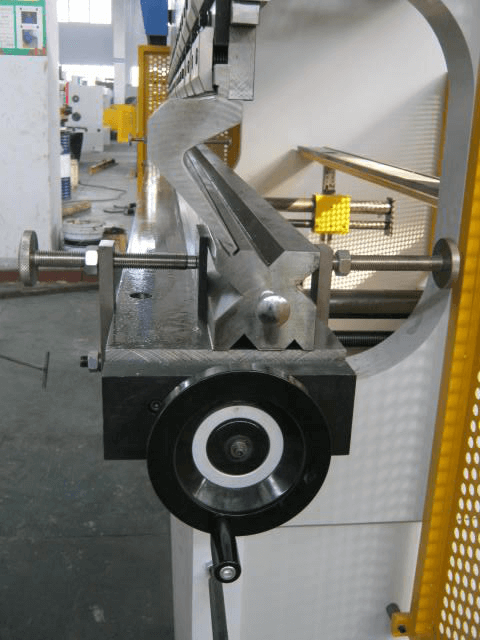

Goosneck tooling ( For Special Sheet Sharp bending) (Optional) |

|

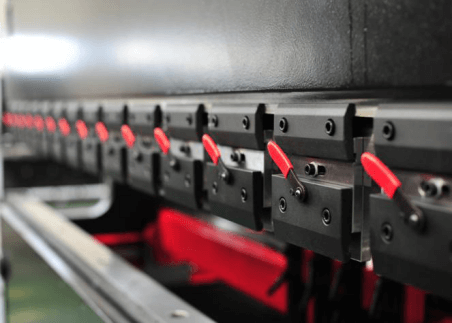

mechanic quick clamping can be equipped as option to reduce the workload and improve working efficiency. (Optional) | |

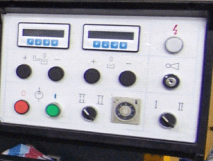

X axis and Y axis position display Resolution:0.1mm or 0.001 inch Holding time setting One side positioning indication Software limitation Power-down memorization (Optional) |

|

SICK DRO X axis and Y axis position display Resolution:0.1mm or 0.001 inch Holding time setting One side positioning indication Software limitation Power-down memorization (Optional) |

|

CE Standard NC controller E21,ESTUN Possible to Programe, With Invertor possible for 2 axis with Position function. (Optional) |

|

MAPER( ITALY) NC controller with Control arm.Easy to operating and Also possible to Auto running by Programe control 2 Axis(Optional) |

|

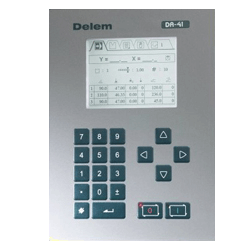

Delem DA 41,CNC controller. Controller 2 Axis, with Servo Motor or Invertor. * High-definition LCD display * Slider stop position control * Backstop control * Angle programming * Mold parameter setting * Escape material control function * 100 programs * Each program has 25 steps * Panel Mount * Servo control, variable frequency control and two-speed AC AC control (Optional) | |

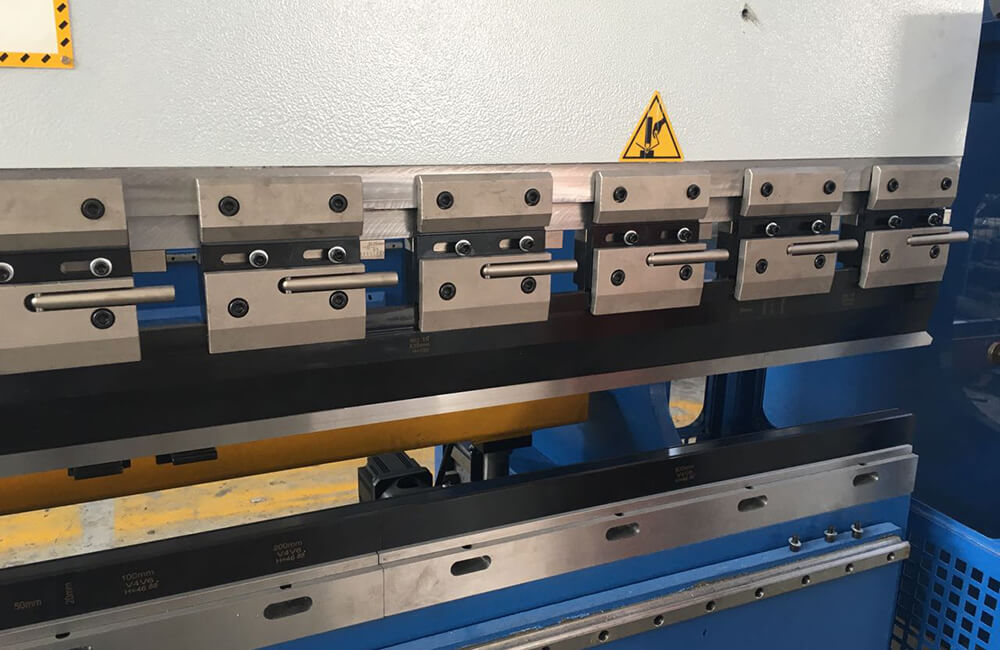

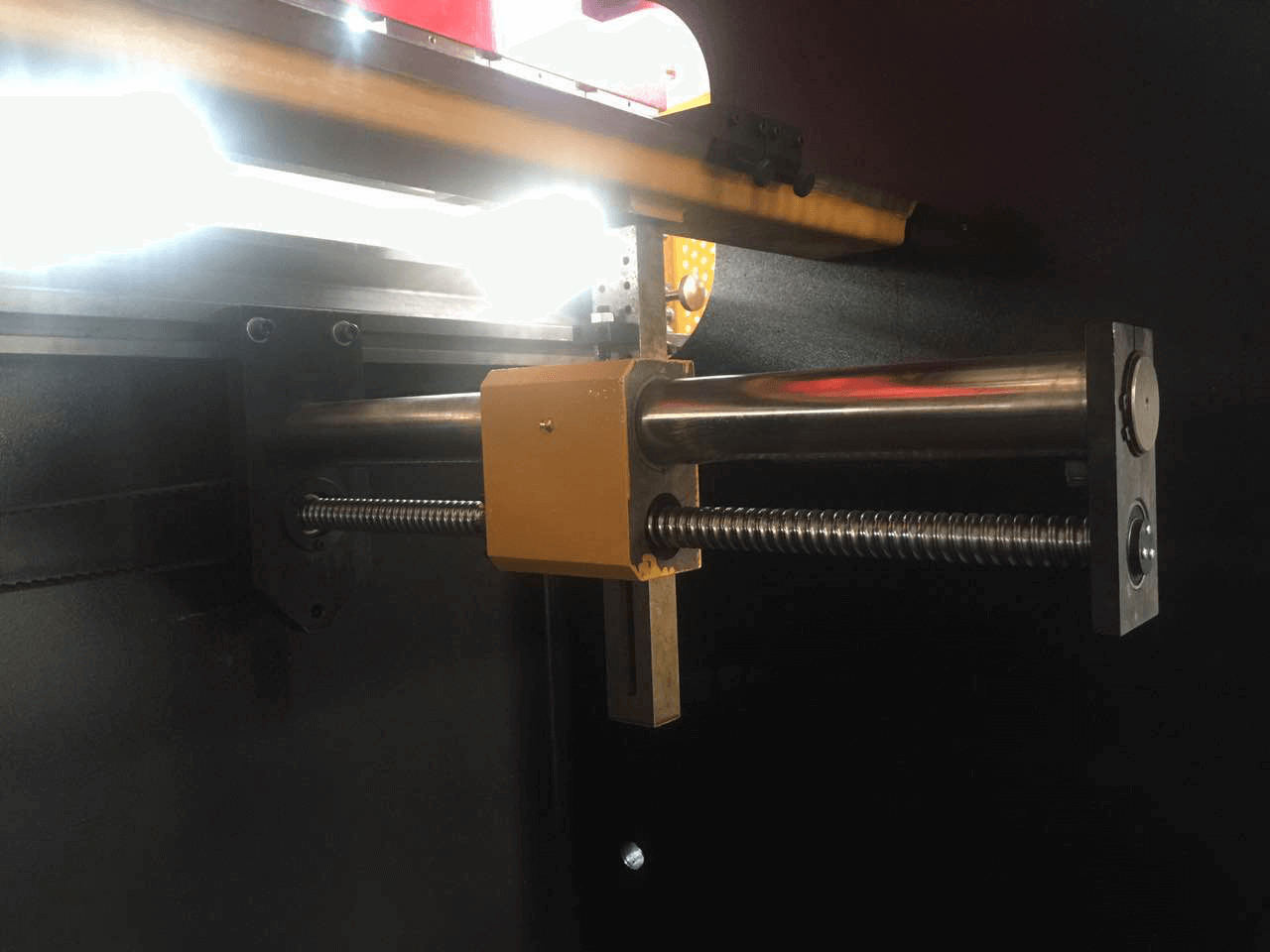

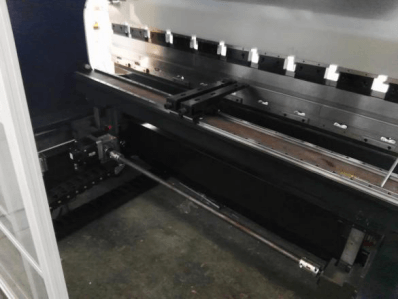

Precision Backgauge, Ball screw + linear guides Daul linear guids Manual R axis ( backgauge up and down ) Or Servo Motor Control(Optional) | For Normal Machine  For CNC Machine with DA41 controller  |

Mechnical Crowning system is adopted to eliminate the effect of the deformed sliding block during bending which may affect bending quality. Adjusted by manual convenient and accurate.(Optional) |

|

DSP Safty light ( Optional) |

|