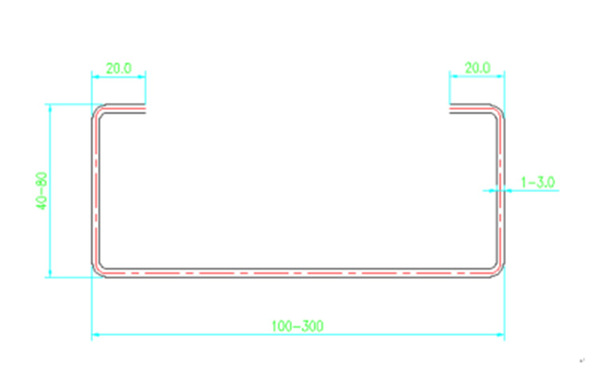

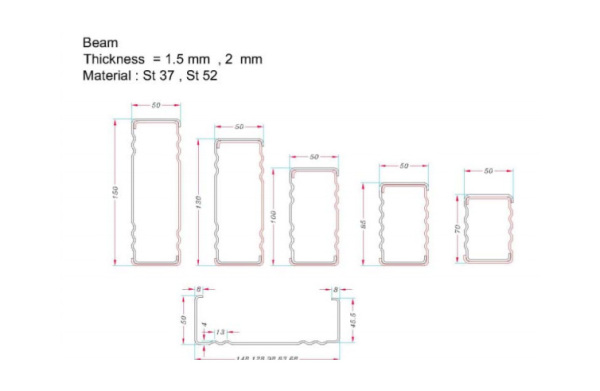

1. Material thickness: 1.5-2.0mm

2. Material yield strength: ST37,ST52

3. Machine producing speed: 10-15m/min (not include punch and cutting time)

4. Cutting Length tolerance: 10±2mm

5. Votage:380V,3P,50hz

Machine Parts:

No | Part | Model and specific | Quantity | Motor power (KW) |

1 | Uncoiler | Manual | 1 | |

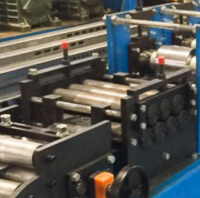

2 | Roll forming machine | Cast Iron structure, chain drive | 1 | 15 KW |

4 | Hydraulic stop cutting | 1 | ||

5 | RunOut table | 2M length | 3 | |

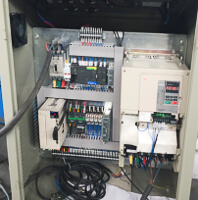

6 | Controller | Whole machine PLC control | 1 | |

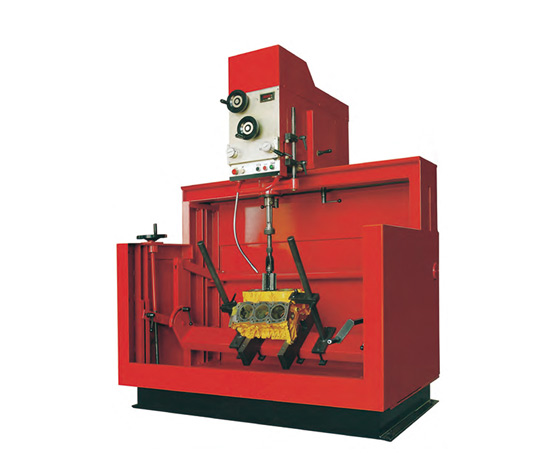

7 | C profile combination machine | Cast Iron structure, chain drive | 1 | 5.5KW |

8 | Spare part | 1 box | 1 |

Machine flow chart:

1. Uncoiling

2. Roller Forming

3. Hydraulic Cutting

4. Output

5. Combination Machine To Joint Two Profile Together

Box beam machine USD34, 000.00 (FOB Shanghai price)

C profile combination machine USD8, 000.00 (FOB Shanghai price)

This price is valid in 30 days!

Payment:

T/T; 30% as deposit; 70% before machine loading container;

Delivery time:

Within 50 days after receipt of the down payment

Manufacturer is available to dispatch technician(s) to buyer’s factory for machine installation, commissioning and worker training.

Buyer affords two-way air tickets, local accommodation and service charge at US$100/day/per technician.

12month since the date of B/L.

The manufacturer can offer spare parts replacing in free charge because of itself quality problem in warranty.

Following items are not included in machine free charge service.

a. Natural disasters;

b. Wrong operation;

c. The machines are refitted by buyer;

d. Machines are moved or transported after installation.

Uncoiler |

|

|

Roll former |

|

|

Hydraulic stop cutting |

|

|

PLC Control cabinet |

|

|

Run-out table |

|

|

C profile combination machine |

|

|

Spare parts |

|

|