C-Z quick interchangeable machine adopts a special structure. The rollers for C & Z are changed very quickly without dismantle any parts. One machine can produce all specifications of C & Z purlins. This machine adopts steel coils as material and gets profiled steel after the process of coiling, cutting, punching, and roll forming. Whole machine adopts PLC controlling, AC frequency speed regulating to fulfill the automatic production, which is very suitable for the metal cold rolled processing industry.

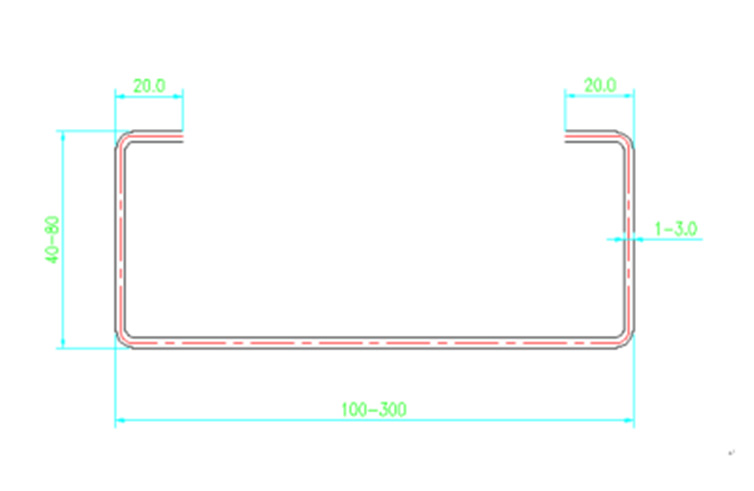

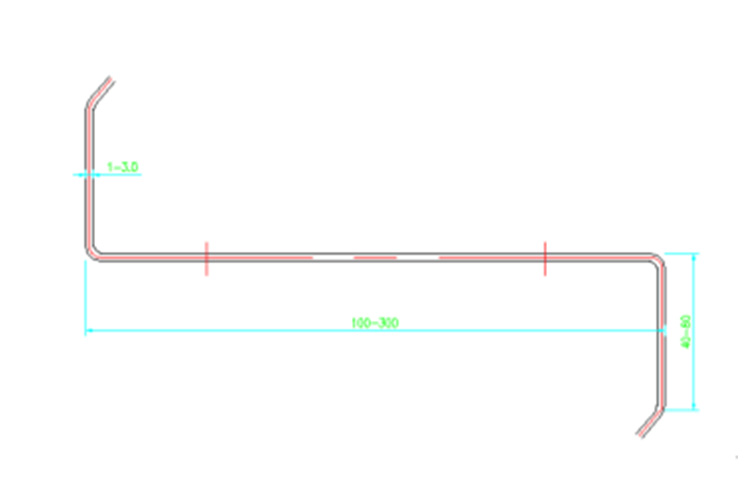

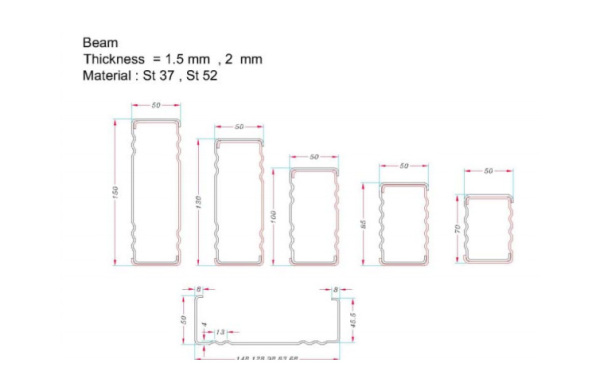

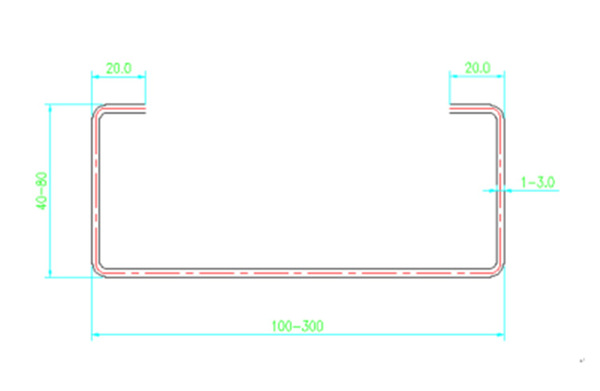

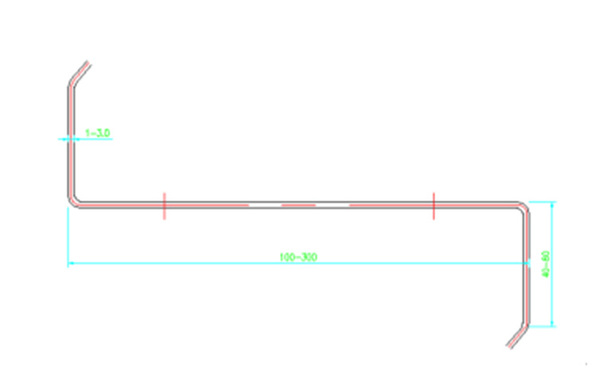

Profile drawing

This is standard drawing, will finalize with customer technical requirements.

Technical process

Passive uncoiling → feeding with guide → leveling → hydraulic punching → roll forming → hydraulic cutting→ output with table

Uncoiler

Uncoiler:passive uncoiling, manual expanding

Weight capacity of uncoiler:5T

Inner diameter of steel coil:Φ508mm

Expanding range:Φ470-Φ530mm

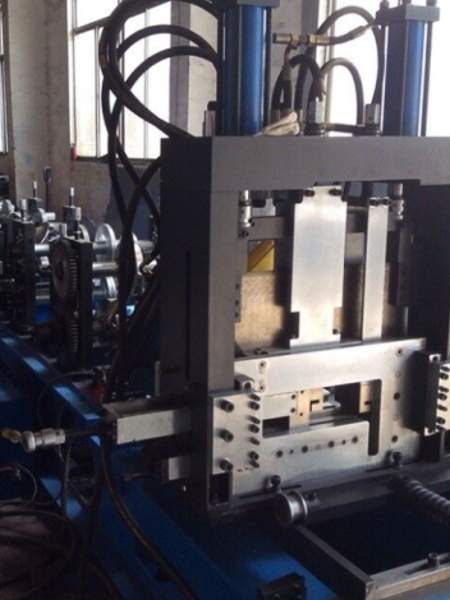

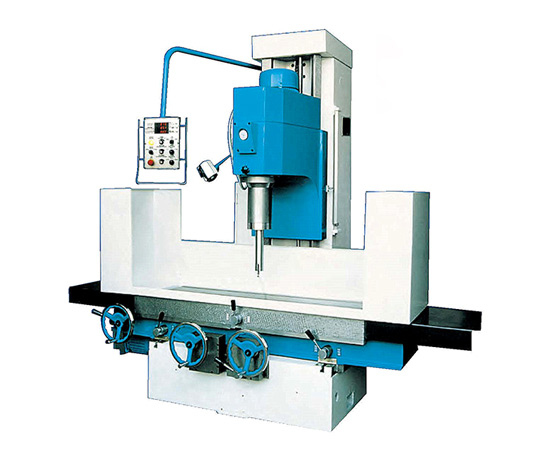

Roll former machine stand

Machine stand:high quality welded profile steel with tempering treatment (CNC Planer type milling, with locating slot)

Guide feeding

leveling unit

Leveler:two rollers for feeding and five rollers for leveling

Motor of leveler:4KW

Diameter of leveling roller:about 80mm

Material of leveling roller:high quality 40Cr

Heat treatment of leveling roller:surface high frequency quenching treatment

Reduction box:Cycloid

Hydraulic punching

Punching unit:hydraulic, 2 stations

Punching mould: 2 (holes can be adjusted)

Material of up/down mould:Cr12MOV

Heat treatment of mould:quenching HRC58-60

Punching tolerance: ±1mm

Motor of hydraulic system:11KW(3 circuits)

Magnetic valve:HUADE(24V safe voltage)

Hydraulic oil pump:plunger pump

Hydraulic system has air cooling

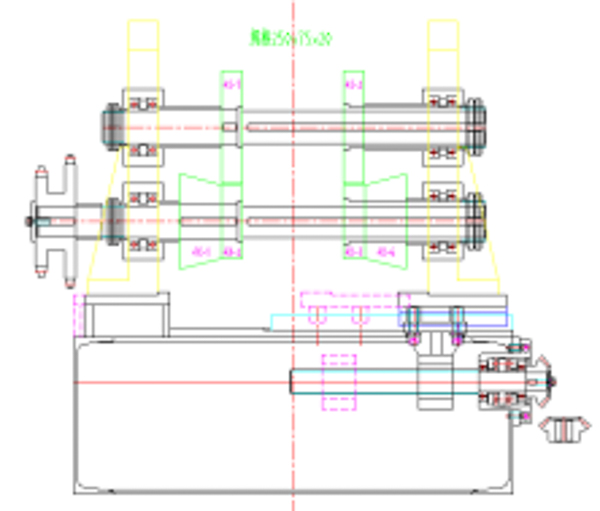

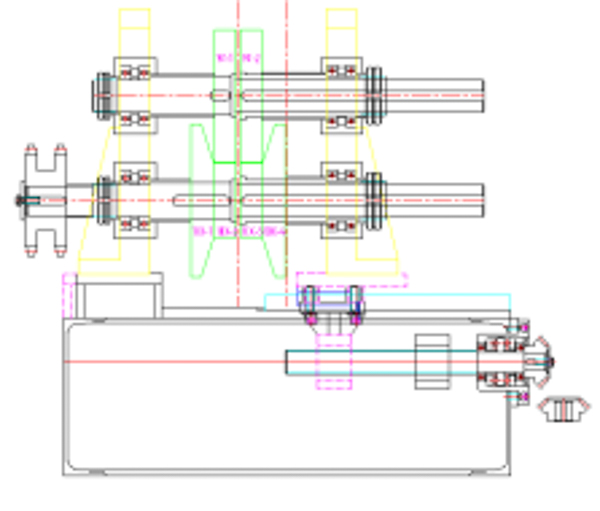

6 roll forming unit

Roll stands adopt cast iron single station which is most heavy and strong.

Auto size changing schematic diagram:

Material of roller shaft:40Cr with heat treatment(HB220-260)

Diameter of roller shaft:Φ75

Motor power of main forming machine:18.5KW

Transverse moving motors:0.75KW*2 (for adjusting height), 1.5KW*1(for adjusting width)

Forming speed:0-18m\min(not includes punching and cutting time)

Forming steps:16 steps + some auxiliary rollers

Thickness of material:1.0-3.0mm

Tolerance of cutting length:±1.5mm

Roll former:1 set(different specification is achieved by stand transverse moving)

Material of roller:GCr15 with quenching treatment(HRC58-62)

Main machine size: 11000mmx1960mmx1300mm

C and Z interchange manually. But C purlin and Z purlin each size changed automatically

Motor for transverse moving: 3KW(0.75x2+1.5KWx1)

Hydraulic universal cutter

Cutting way:hydraulic, after forming, and universal sizes

Material of cutter blade:Cr12MOV

Heat treatment of mould:quenching HRC58-60

Cutting tolerance: ±1mm

Output tables 2000mm long * 2 pcs

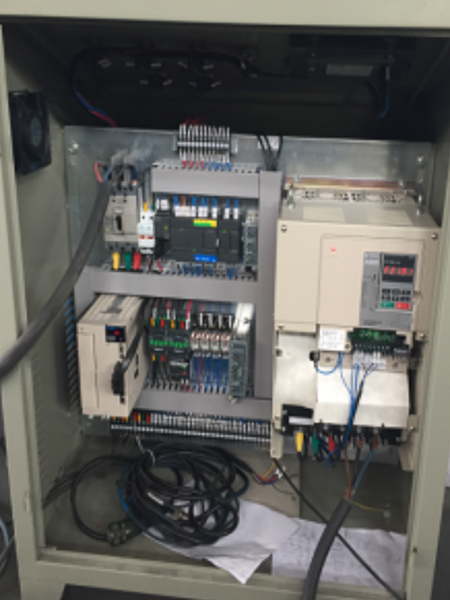

Electrical controlling system

Transducer:Yaskawa, Japan

Computer adopts PLC, Panasonic, Japan

Operating board:MCGS

Encoder:KOYO, Japan

Relay: Chint

Equipment includes

This equipment includes uncoiler, main roll forming machine(with feeder, leveler, roll former, hydraulic punching and cutting), receiving table, hydraulic system, electrical control system and so on.

Delivery time:70 days

Price: USD45, 000.00(FOB Shanghai port)

This price is only valid for 15 days.

Service:

Manufacturer is available to dispatch technician(s) to buyer’s factory for machine installation, commissioning and worker training.

Buyer affords two-way air tickets, local accommodation and service charge at US$100/day/per technician.