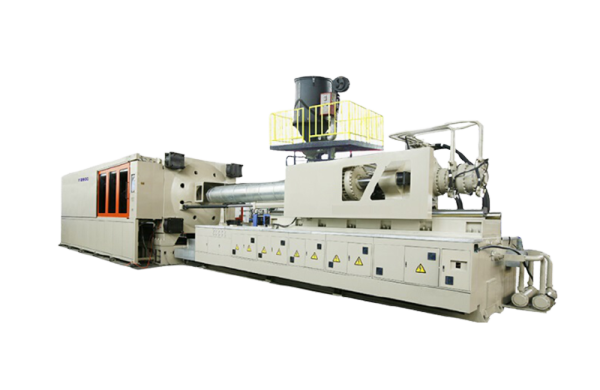

Item | unit | technical parameter | ||

(Screw diameter) | mm | 125 | 135 | 145 |

(Screw L/D ratio (L/D)) | 23.7 | 22 | 20.4 | |

(Theoretical shot volume) | cm3 | 8095 | 9442 | 10893 |

( Injection weight (PS)) | g | 7366 | 8592 | 9912 |

(Injection rate) | g/s | 975 | 1138 | 1312 |

(Plasticizing capacity (PS)) | g/s | 128.6 | 150 | 173 |

(Injection pressure) | MPa | 191 | 163 | 141 |

(Screw speed) | r/min | 0-75 | ||

(Injection stroke) | mm | 660 | ||

Clamping force | kN | 18000 | ||

(Space between tie bars ) | mm×mm | 1500×1400 | ||

(Mold thickness) | mm | 600-1500 | ||

(Mold stroke) | mm | 1500 | ||

(Ejector force) | kN | 300 | ||

(Ejector stroke) | mm | 350 | ||

(No. of ejector) | 29 | |||

(Pump motor power) | kW | 56×3 | ||

(Heater power) | kW | 102.5 | ||

(Hydraulic tank capacity) | L | 2330 | ||

(Out size of the machine) | m | 15.4*3.5*4.5 | ||

(Weight of the machine) | t | 102 | ||

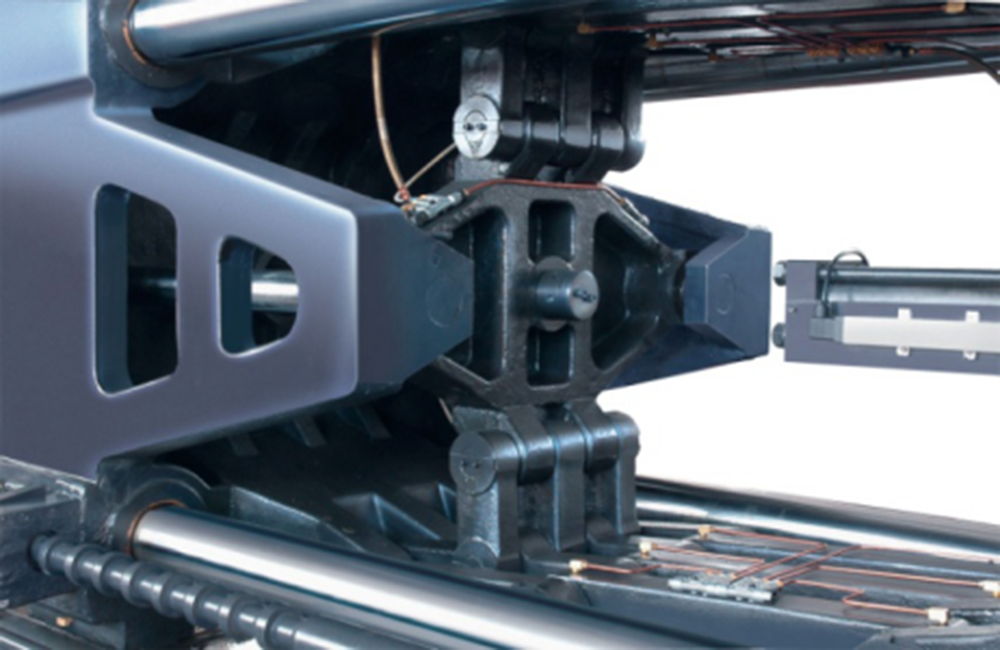

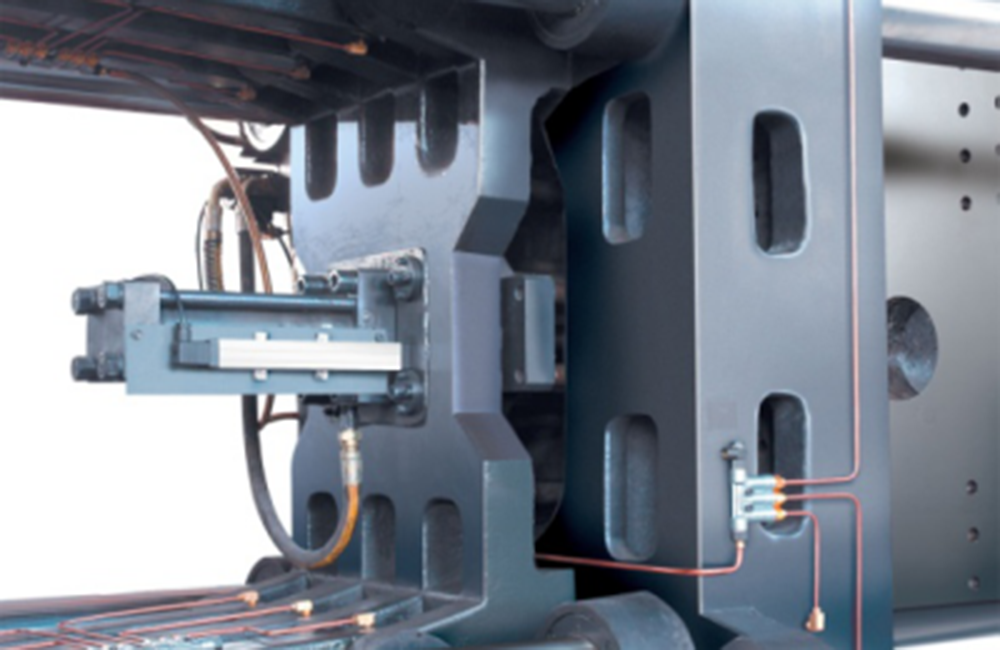

CLAMPING UNIT |

New type 5-point toggle device with the advantage of stable movement curve and gentle shock High-quality mould platen with enough intensity to ensure no out of shape if high-pressure clamping Hard chrome plated high tensile strength tie bars made of superior alloy with a good wear and corrosion resistance ability Wear-resistant guide for moving platen Transducer control clamping stroke Many step control for speed and pressure of clamping and opening Ejection device offer dwell, single, more, vibration function Differential high speed clamping Low pressure mould protection function Hydraulic mould height adjustment drived by gear with rough and fine operation Mechanical and electrical dual safety interlock Automatic centralized lubrication system with far pressure detector |

INJECTION UNIT |

nitrided screw and barrel with long service life Smelted screw with big L/D ratio to the result of high quality plasticizing and color-fixing. Double injection cylinder device featured compact construction and good equilibrant. Transducer control injection stroke The speed of low speed and large torque hydraulic motor can be freely adjusted. Screw back pressure control and nozzle anti-leakage control Movable hopper for easy remove material Injection carriage can be generally used with the function of slacking, re-feeding or fixed-feeding Many steps speed and pressure of injecting and holding are controlled by time or position or both Equipped with reverse device to be easily removed and cleaned |

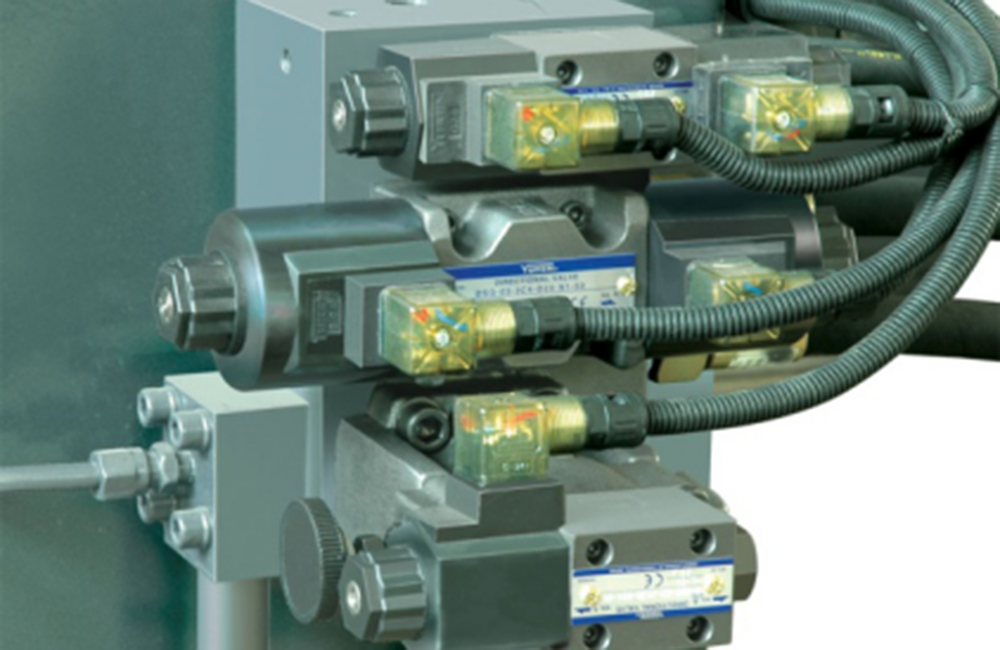

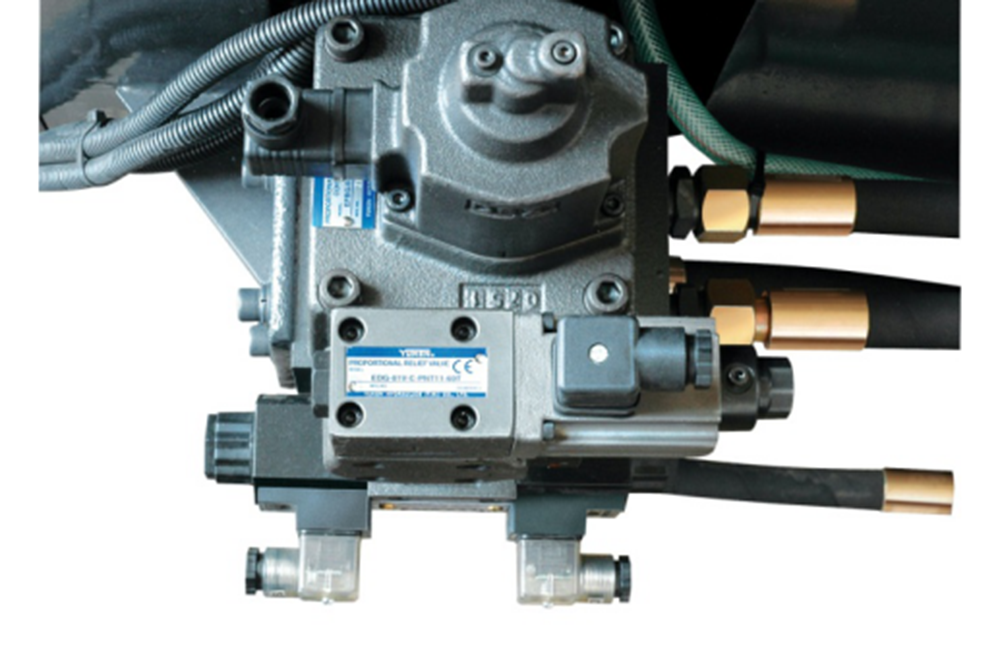

HYDRAULIC UNIT |

proportional pressure and flow control with the advantage of fine adjustment and high precision know-how manifold design, compact, reasonable and fast respond imported world famous hydraulic valves imported world famous hydraulic sealing rings import technology hydraulic hose and fittings low noise hydraulic system oil tank with inner stainless steel container precision oil filter oil cooler |

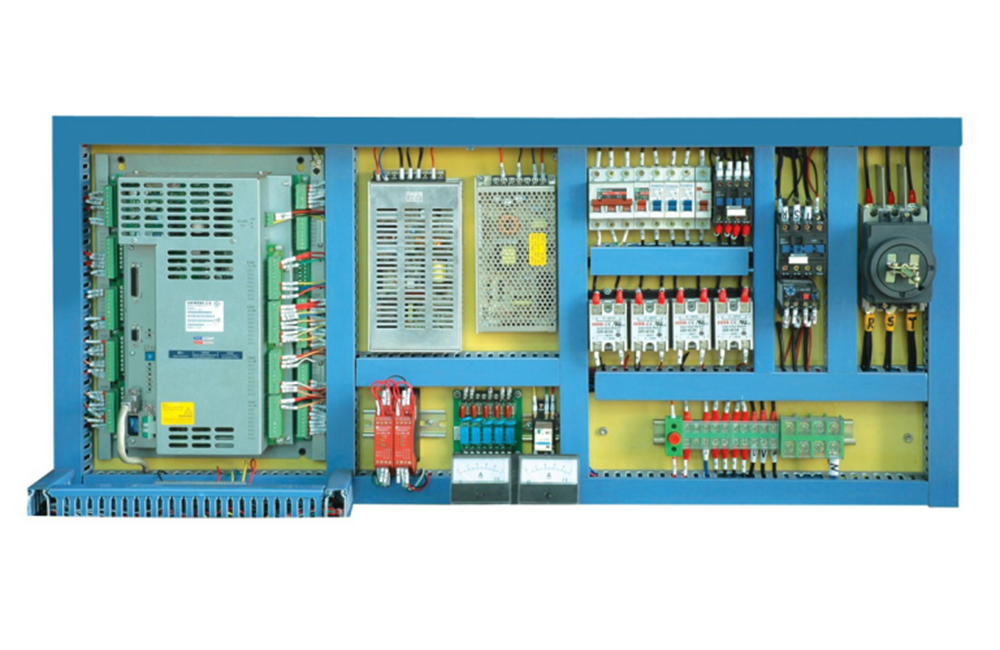

CONTROL UNIT |

The computer is imported from Industry family. The LCD displaying screen with high clarity has Chinese and English language to display World famous electrical components Close-loop PID temperature control with the advantage of high precision. Deviation preset between high and low temperature. And break control for temperature sensor. Alarming system in case of cold start and no material in hopper Transducer control the injection and opening stroke to accuracy of ±0.05mm 99 steps speed control for increasing and reducing to suit for different technology demands Self-diagnostic and trouble alarm function Parameters lock function to avoid being changed 100 sets of production parameters can be stored into the computer memorial software Machine can record the quantity of products and automatically stop if up to the required quantity. Emergency stop device Alarm lamp |

Name | Brand | Origin |

Reversal Hydraulic Valve | VICKERS | USA |

Proportional Hydraulic Valve | VICKERS | USA |

Hydraulic Oil Pump | REXROTH | GERMANY |

Hydraulic Motor | INTERMOT | ITALY |

Hydraulic Hose | KIMBERLEY | GERMANY |

Sealing Rings | VALQUA | JAPAN |

Computer Control System | TECHMATION | TAIWAN |

Display Screen | HITACHI | TAIWAN |

Linear Transducer | GEFRAN | ITALY |

Limit Switch | National | JAPAN |

Proximity Switch | FORTEK | TAIWAN |

Solid State Relay | FORTEK | TAIWAN |

Contactor | SCHNEIDER | FRANCE |

High-temperature Wire | JAPAN | |

Air-break Switch | SCHNEIDER | FRANCE |

Automatic Lubrication | SANLANG | CHINA |

Electricity Servo Motor | PHASE | ITALY |

Servo driver | AUSTONE | TAIWAN |

No. | Name | Qty. |

1 | Operation Manual | one book |

2 | Heating band for Barrel | 2pcs |

3 | Heating band for Nozzle | 2pcs |

4 | Oil seal for Injection | 1set |

5 | Oil seal for Clamping | 1set |

6 | Oil seal for ejector | 1set |

7 | Solid State Relay | 2pcs |

8 | Fuse | 1pc |

9 | Tool box | 1set |

10 | Level pad | 1set |

11 | Mould clip | 1set |

12 | Proximity Switch | 2pcs |

13 | Limit switch | 1pc |

14 | Electrical plug | 2pcs |

15 | Filter core | 1pc |

16 | Hopper | 1pc |